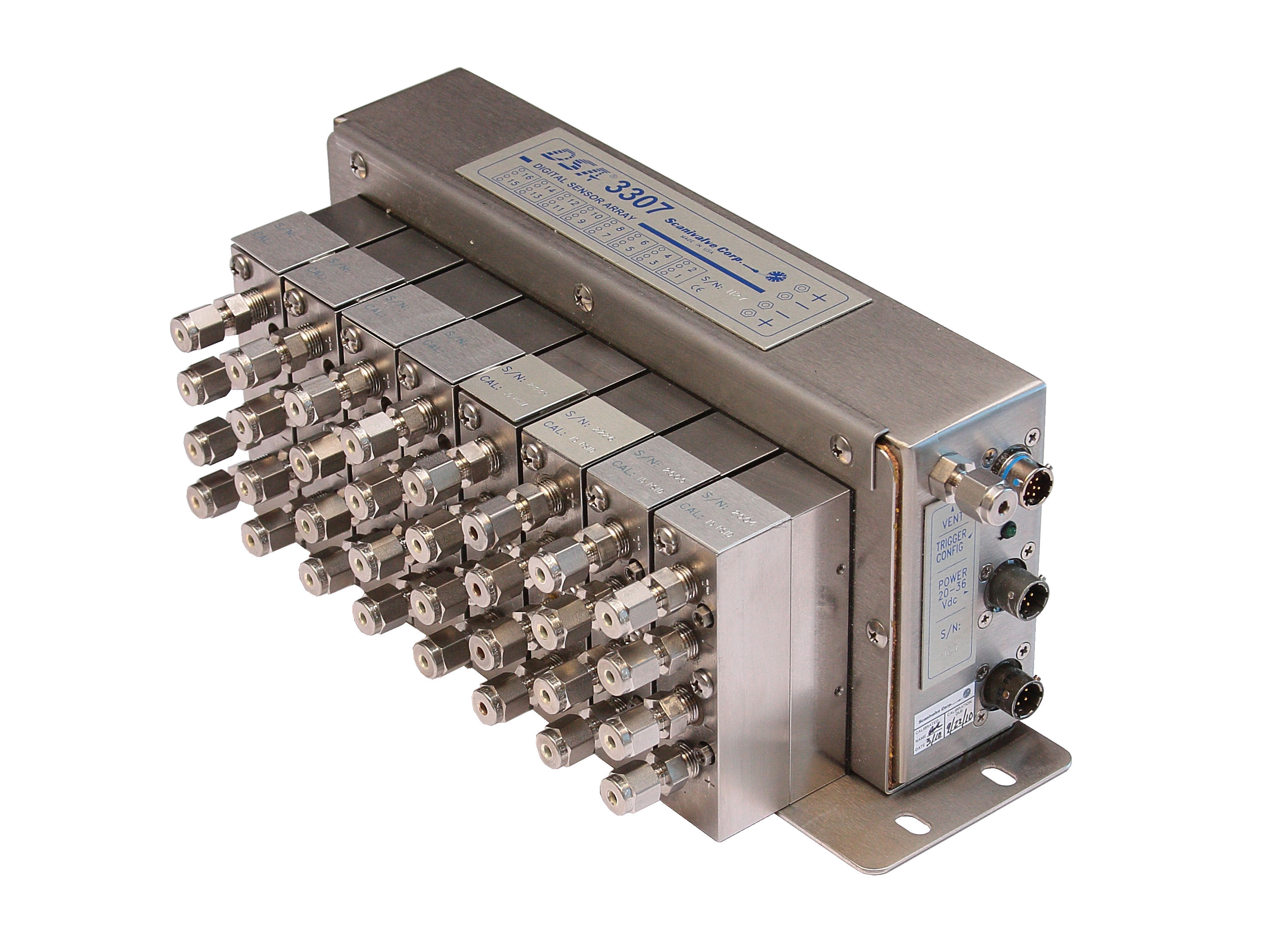

19″ Rackmount Enclosure with 16-Channel Pressure Scanners

DSA3016 Features and Specifications

- ±0.05% Full Scale, Long Term Accuracy (most ranges)

- 0 – 750psi Pressure Range

- Standard, Dual Range, and True Differential Module Configurations

- Isolate / Calibrate / Purge valve

- Temperature Compensated Pressure Sensors

ENCL4000 Features and Specifications

- IEEE1588-2008v2 PTP Compliant (NEW)

- Direct Ethernet Connection for TCP, UDP, and FTP data transfers

- Scan Rates up to 625Hz (samples per channel per second)

- 16-bit A/D Converters

- 3 Integrated Solenoids for Control Pressure

- Up to 128 Channels (8x DSA3016 modules)

Overview

The DSA3016 , or Digital Sensor Array, is a 16 channel analog pressure scanner designed to be mounted in the DSAENCL4000, 19″ Rack mount enclosure. Each DSA3016 modules incorporates 16 temperature compensated piezoresistive pressure sensors, along with a pneumatic calibration valve. Field replaceable sensors assure that downtime is minimized in the unlikely event of sensor damage. Up to 8x DSA3016 modules can be used in a single 19 inch rack enclosure. Each installed DSA module can be a different pressure range or pneumatic configuration, such as true differential or common differential modules. Long term system accuracy of the DSA’s pressure sensors is achieved for up to 6 months, and can be calibrated and validated in the field to maintain accuracies.

The DSAENCL4000 pressure acquisition system represents the next generation of intelligent electronic pressure scanning. The state-of-the-art DSP technology is at the heart of our new 19 inch rack mounted DSAENCL4000 enclosure. Located on the backplane of the enclosure, the Digital Signal Processor (DSP) is a programmable device capable of extremely fast math functions that operate on the data stream in real time. All pressure measurements sensed at each channel of the installed DSA3016 modules are converted into Engineering Units, which are output using TCP, UDP or FTP protocol over the Ethernet connection. The DSP processor also controls the actuation of the DSA’s internal calibration valve to perform online zero calibrations or purge functions. The DSAENCL4000 will automatically read the serial number, pressure range, etc. of each installed DSA3016 module and its location in the enclosure using each DSA module ‘s unique ID chip. The enclosure utilizes a pressure temperature look-up table for each installed DSA module to compensate the pressure sensors for temperature changes, thereby reducing thermal errors. As of September of 2021, the DSAENCL4000 is IEEE1588-2008v2 Precision Time Protocol compliant for high accuracy synchronization with PTP Networks.

Applications

The DSA3016 Digital Sensor Array and DSAENCL4000 combination is ideal for measuring pressures on turbomachinery, turbine engines, compressors, and other industrial applications where ambient temperatures may vary. The DSA temperature compensated pressure sensors are more than ten times less sensitive to temperature than typical piezoresistive pressure sensors. Each enclosure can scan up to 128 channels (inputs), and multiple units can be installed in a single 19″ rack mount enclosure. Precision Time Protocol can be used to synchronize several ENCLs together to provide high accuracy time correlation. DSA3016 modules have a front panel power cutoff switch that allows them to be “Hot Swappable” without having to power down the system. They also have an illuminated power switch that blinks when scanning. The modules can also be configured to have the inputs located on front of the module, for easy access, or on the back of the modules for easy change-over and more permanent installations. The DSAENCL4000 enclosure has an Ethernet link and activity LED on the front.

The DSAENCL4000 and DSA3016 can be used in applications such as:

- Compression stage research and testing

- Power generation

- Engine test and engineering

- Steam turbine efficiency and performance

- Wind turbine blade monitor and control systems

- Wind and building engineering

- Flight performance and testing

- Educational and research facilities

- And many more

Documentation

-

-

-

- DSAENCL4000 Hardware & Software Manual

(3.5 MB)

(3.5 MB) - DSAENCL4000 & DSA3016 Data Sheet

(651.6 KB)

(651.6 KB) - Legacy DSA3016 Manual

(585.6 KB)

(585.6 KB)

- DSAENCL4000 Hardware & Software Manual

-

-

3D Models

-

-

- DSAENCL4000 3D Model

(39 MB)

(39 MB) - DSA3016-RA 3D Models

(4 MB)

(4 MB)

- DSAENCL4000 3D Model

-